The Ultimate Guide to Choosing the Right Drill for Every Job

As a tradesperson, DIY enthusiast, or homeowner, you know the importance of having the right tools for the job. A good drill is an essential part of any toolkit, but with so many options available, choosing the right one can be daunting. Whether you’re drilling into wood, metal, or masonry, the correct drill can make all the difference in terms of efficiency, accuracy, and safety.

In this comprehensive guide, we’ll walk you through the key considerations for selecting the perfect drill for your specific needs. We’ll explore the various types of drills, their features, and the tasks they’re best suited for. By the end of this article, you’ll be equipped with the knowledge to make an informed decision and find the ideal drill for your next project.

What to Expect from This Guide:

- A clear understanding of drill types and their applications

- Expert advice on selecting the right drill for specific materials and tasks

- Insights into advanced features and technologies

- Guidance on balancing budget and quality

- Maintenance and safety tips to ensure optimal performance

Let’s get started!

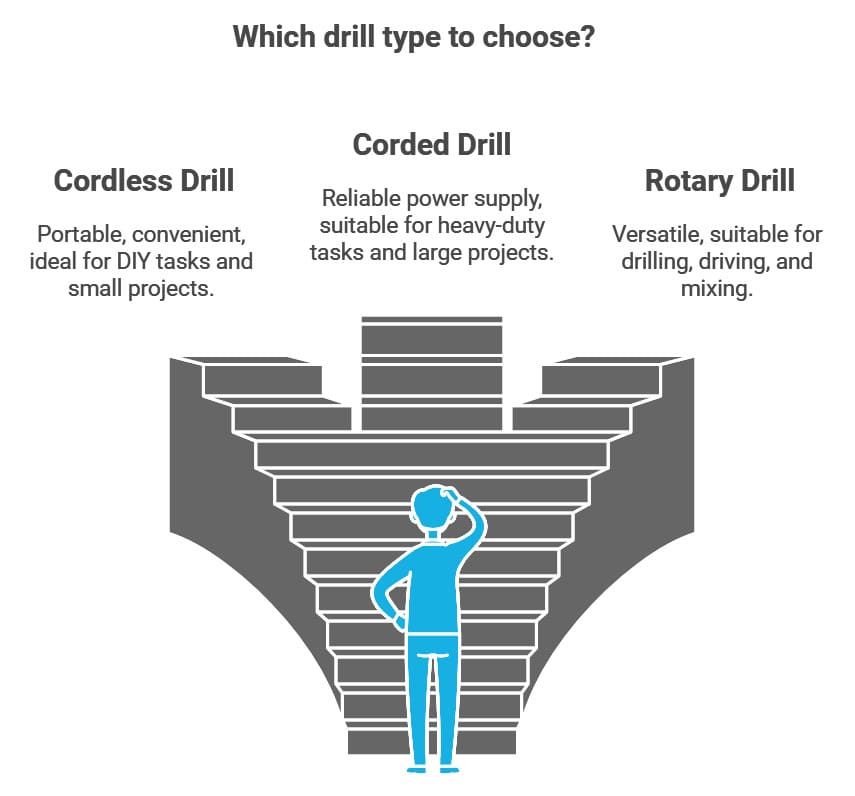

Drill Types: Understanding the Options

With numerous drill types available, it’s crucial to understand their unique characteristics, benefits, and applications. Let’s delve into the primary drill categories:

1. Cordless Drills

- Portable and convenient

- Ideal for DIY tasks, small projects, and tight spaces

- Typically 10.8V to 18V

- Popular brands: Bosch, Makita, DeWalt

2. Corded Drills

- Reliable power supply

- Suitable for heavy-duty tasks, large projects, and continuous use

- Typically 240V

- Popular brands: Bosch, Makita, Hitachi

3. Rotary Drills (also known as Power Drills)

- Versatile and adaptable

- Suitable for drilling, driving, and mixing

- Often feature adjustable torque and speed

- Popular brands: Bosch, Makita, DeWalt

4. Hammer Drills

- Designed for heavy-duty drilling into masonry and concrete

- Utilise a hammering action to break up material

- Typically feature a dedicated hammer function

- Popular brands: Bosch, Makita, Hilti

5. Impact Drivers

- High-torque output for driving large screws and bolts

- Often feature adjustable speed and torque

- Popular brands: Makita, DeWalt, Bosch

6. Right-Angle Drills

- Compact design for tight spaces

- Ideal for plumbing, electrical, and automotive work

- Popular brands: Bosch, Makita, Milwaukee

7. Masonry Drills

- Specialised for drilling into concrete, brick, and stone

- Typically feature tungsten carbide or diamond-coated bits

- Popular brands: Hilti, Bosch, Makita

8. Specialty Drills

- Glass drills for delicate glasswork

- Tile drills for ceramic and porcelain tiles

- Metal drills for drilling into steel and aluminium

When choosing a drill, consider the specific task, material, and desired outcome. This will help you select the most suitable drill type for your needs.

Read More: 10 Tips to Quickly Sell Your Tools Online

Job-Specific Drill Selection

Now that you’re familiar with the various drill types, let’s explore how to match the right drill to your specific task.

Drilling Materials:

Wood Drilling:

- Softwood: cordless drill with wood bits (10-18V)

- Hardwood: corded drill with wood bits (240V)

- Large holes: Forstner or hole saw bits

Metal Drilling:

- Thin metal: cordless drill with HSS (High-Speed Steel) bits (10-18V)

- Thick metal: corded drill with cobalt or tungsten carbide bits (240V)

Masonry Drilling:

- Concrete: hammer drill with tungsten carbide or diamond-coated bits

- Brick: hammer drill with tungsten carbide bits

- Tile: tile drill with ceramic or porcelain bits

Drywall Drilling:

- Cordless drill with drywall bits (10-18V)

- Hollow-wall anchors for secure fixing

Glass Drilling:

- Specialty glass drill with diamond-coated bits

- Low-speed, high-torque setting

Read More: The Eco-Friendly Way to Sell Unwanted Tools

Task-Specific Drills:

Driving Screws:

- Impact driver with screwdriver bits

- Cordless drill with adjustable torque

Mixing Materials:

- Drill with mixing paddle attachment

- Corded drill for continuous use

Precision Drilling:

- Cordless drill with precision bits (10-18V)

- Steady-hand grip or drill press

Drill Bit Selection:

- Material-specific bits (wood, metal, masonry)

- Bit size and type (twist, spade, hole saw)

- Coating (tungsten carbide, diamond, HSS)

By considering the material, task, and desired outcome, you’ll choose the optimal drill for your project.

Read More: Ryobi ONE+ Camping Gear: What to Pack for Your Next Trip

Key Features to Consider

1. Power Source Considerations

When selecting the perfect drill, several essential features come into play. First and foremost, consider the power source. Cordless drills offer convenience, portability, and reduced cord clutter, making them ideal for tasks that require flexibility. On the other hand, corded drills provide reliable power, reduced battery worries, and cost-effectiveness, suited for heavy-duty tasks or continuous use.

2. Voltage and Amp-Hours: Understanding the Numbers

Voltage and amp-hours are also crucial factors. Higher voltage drills (18V-24V) deliver increased power for demanding tasks, while lower voltage drills (10.8V-14.4V) are suitable for lighter tasks and offer reduced weight. Amp-hours (Ah) measure battery life, with higher Ah ratings providing longer runtime.

3. Speed and Torque: Precision Control

The drill’s speed and torque capabilities are vital for precise control. Variable speed and adjustable torque allow for tailored performance, preventing damage to screws and materials. High-torque drills are perfect for heavy-duty tasks, large screws, and bolts.

4. Ergonomic Design for Reduced Fatigue

Ergonomics and comfort play a significant role in reducing fatigue and improving control. Look for drills with ergonomic grips, balanced weight distribution, and adjustable handles to accommodate different hand sizes.

5. Durability and Build Quality: A Lasting Investment

Durability and build quality are equally important. A metal gear housing and high-quality motor ensure efficiency, reliability, and longevity. Weather-resistant designs protect against dust, moisture, and extreme temperatures.

6. Safety Features for Protection

Safety features, such as overload protection and thermal protection, prevent motor damage and overheating. LED lights provide improved visibility and reduce eye strain.

7. Accessories and Storage: Convenience and Protection

Additionally, consider the availability of accessories and storage options. A suitable chuck size ensures compatibility with various drill bits, while included drill bits offer convenience and cost-effectiveness. A storage case protects the drill, bits, and accessories.

8. Warranty and Support: Peace of Mind

Lastly, evaluate the manufacturer’s warranty and customer support. A comprehensive warranty provides peace of mind, protecting against defects, while reliable customer support assists with queries, repairs, and maintenance.

9. Balancing Features and Budget

When balancing features, quality, and price, consider long-term costs, such as battery replacement and maintenance. By carefully evaluating these key features, you’ll find the ideal drill for your needs, ensuring efficient, safe, and successful projects.

Read More: How Much Do Cash Converters Pay for Tools?

Choosing the right drill for your specific needs can be a daunting task, but by considering the key factors outlined in this guide, you’ll be well-equipped to make an informed decision.

Have an unused drill collecting dust? Consider selling it to Sell Tools Online! We buy used and new drills from leading manufacturers. Get paid within 24 hours and let Sell Tools Online help you declutter and upgrade your toolbox!